Solutions

teps

TEPS

(Total Enterprise Process Solution)

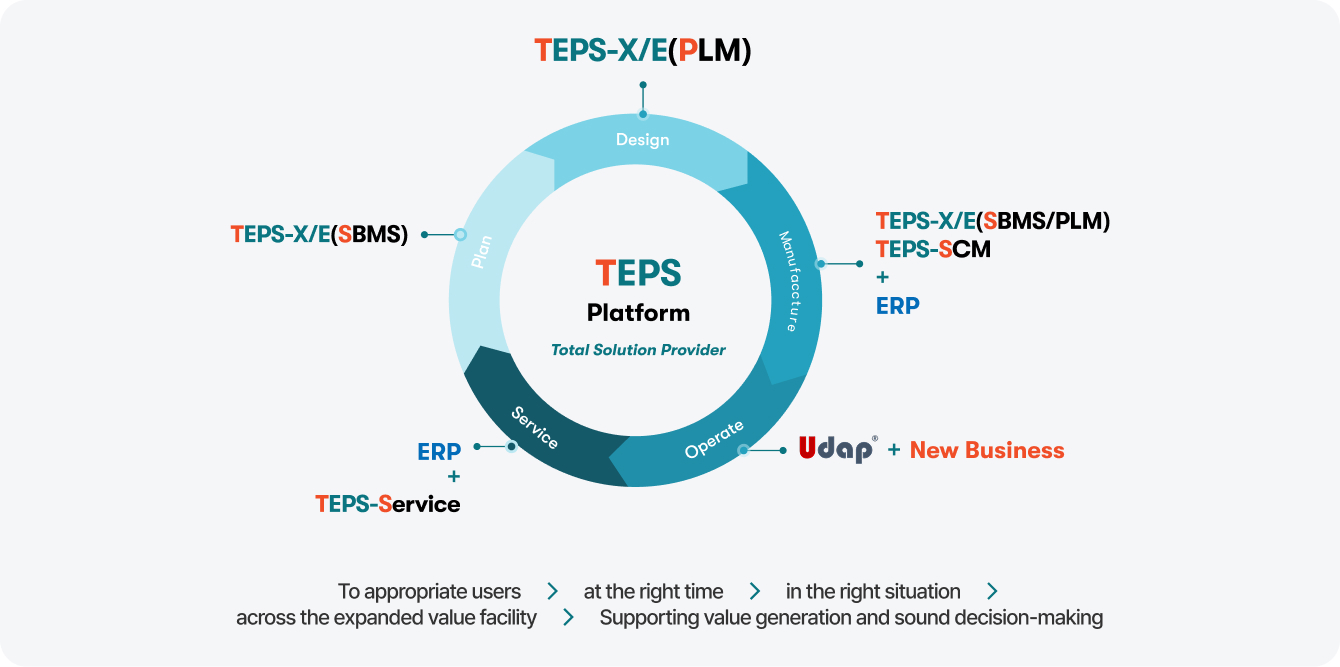

TEPS (Total Enterprise Process Solution) is an integrated design and system-building solution that bridges information systems

with business needs, enabling the design, development, implementation, and operation of an active and efficient information system.

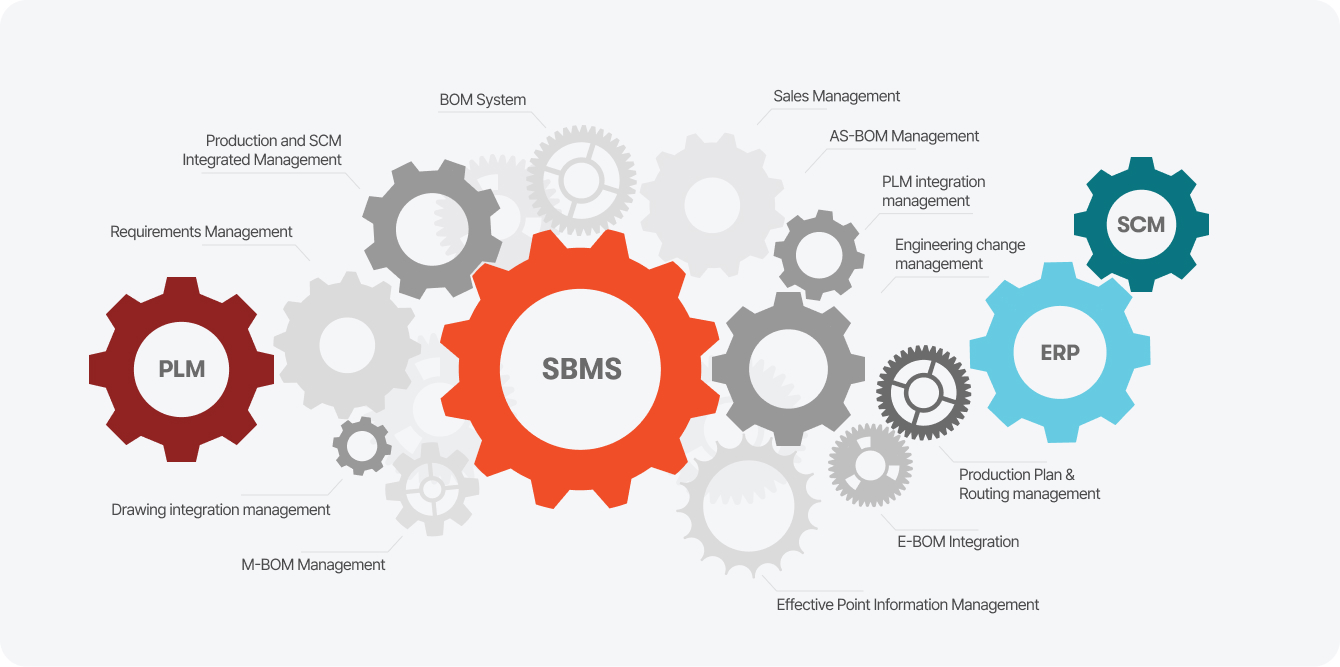

TEPS, consisting of SBMS, PLM, and SCM, creates a connected system aligned with the business process

from ordering to shipment and service, realizing an efficient and optimized single platform.

UDS's TEPS consists of the best phased systems, optimized for the business process.

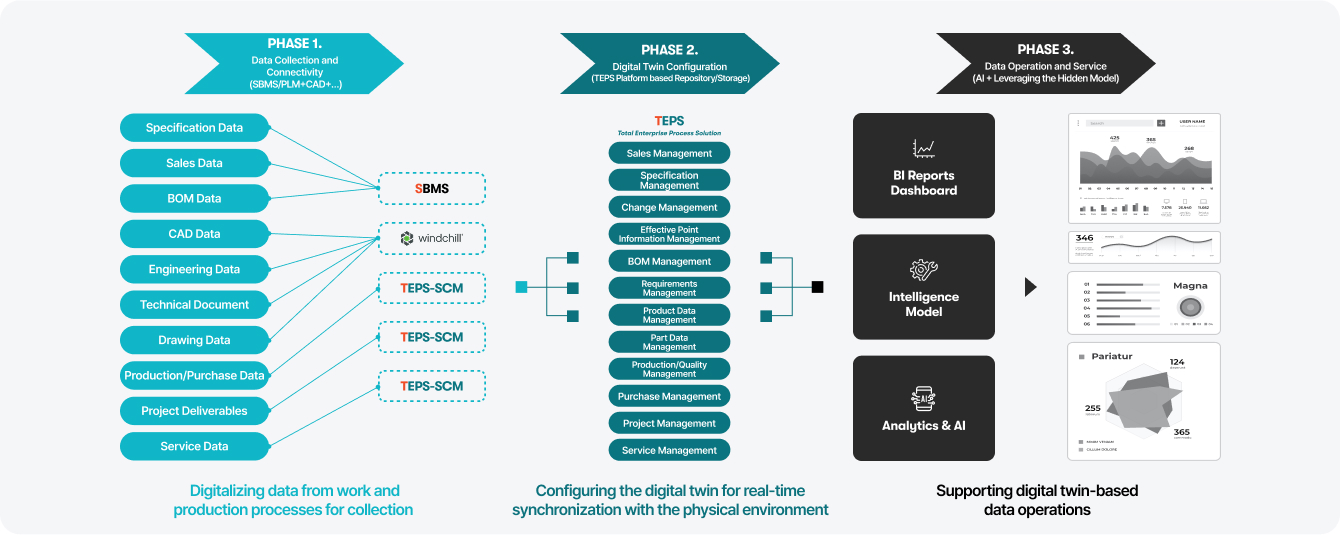

- PHASE 1 Collecting and utilizing offline data across overall business processes as digital data

- PHASE 2 TEPS Creating a digital twin based on the TEPS solution and synchronizing it with the business environment in real time

- PHASE 3 Offering a real-time data-driven dashboard, advancing innovation through AI and BI solutions

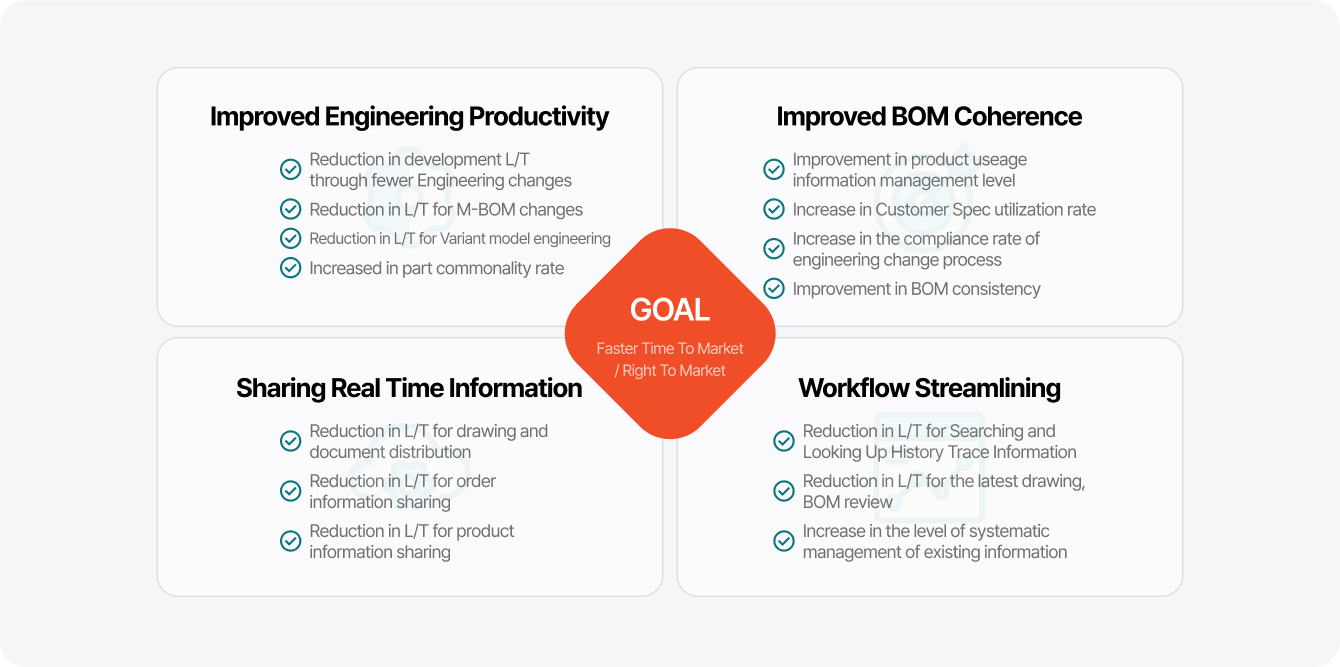

Benefits of Introduction

- 1 Minimizing time loss by automating tasks previously handled manually

- 2 Maintaining interdepartmental data coherence and consistency

- 3 Efficient Management of Specifications and BOM through the System

- 4 By establishing BOM for each specification, design sharing is facilitated

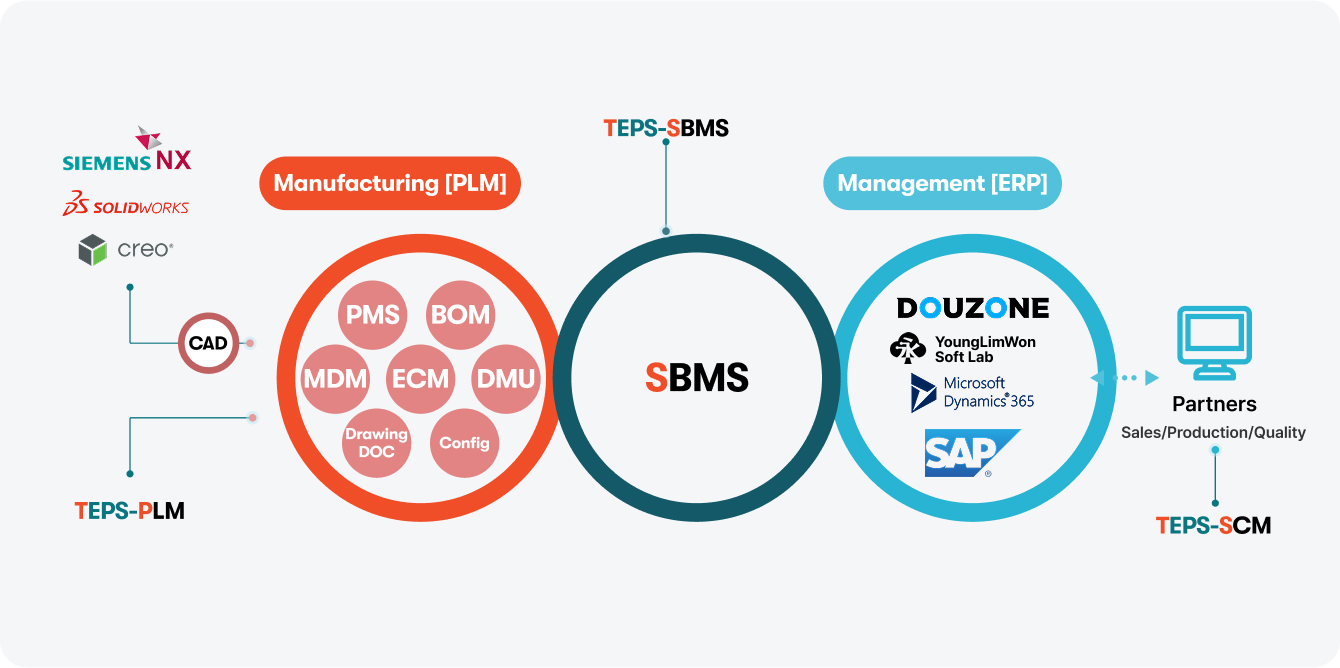

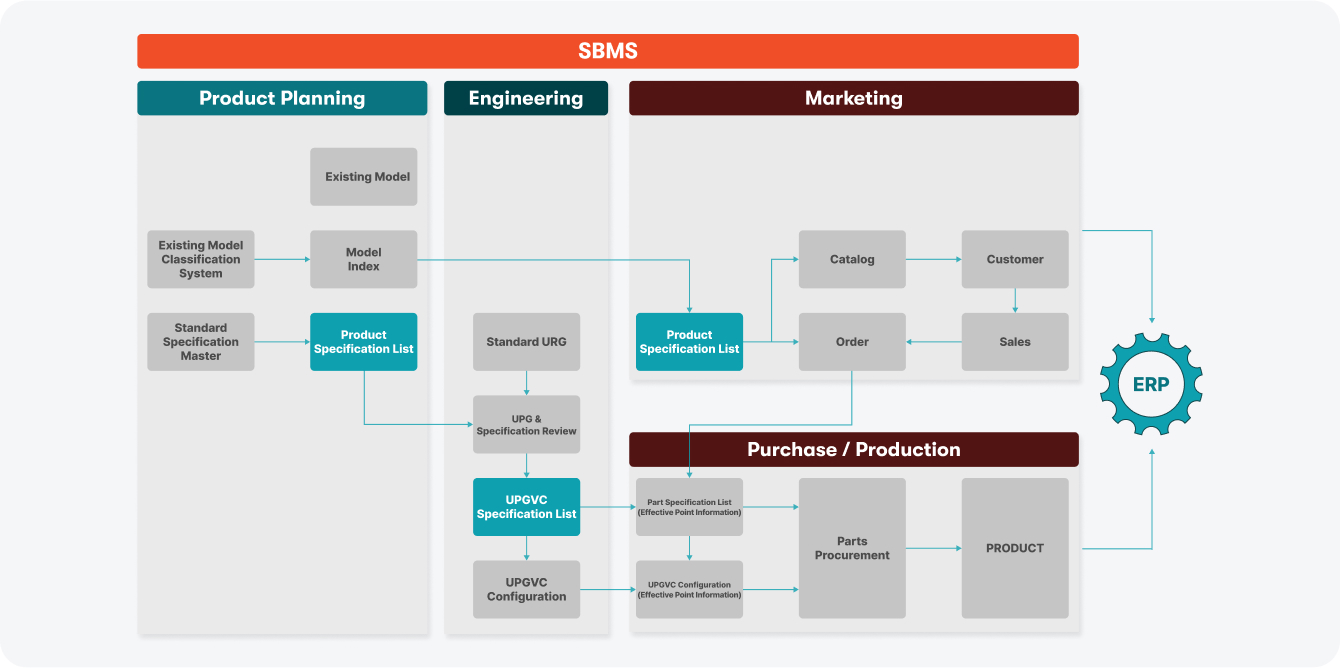

The TEPS-SBMS (Specification & BOM Management System) solution manages corporate standard information through BOM creation

by product, part specification, and purpose, and builds a unified platform by integrating with systems such as PLM, ERP, and more

It enables a consistent Spec & BOM management process, allowing the marketing, production, and purchasing departments

to respond based on product specifications from the product planning department and part specifications from the design department.

It supports BOM management capable of responding to the mass customization industry, and ensures data consistency, coherence,

and transparency by sharing phased information with clients, part manufacturers, and partners.

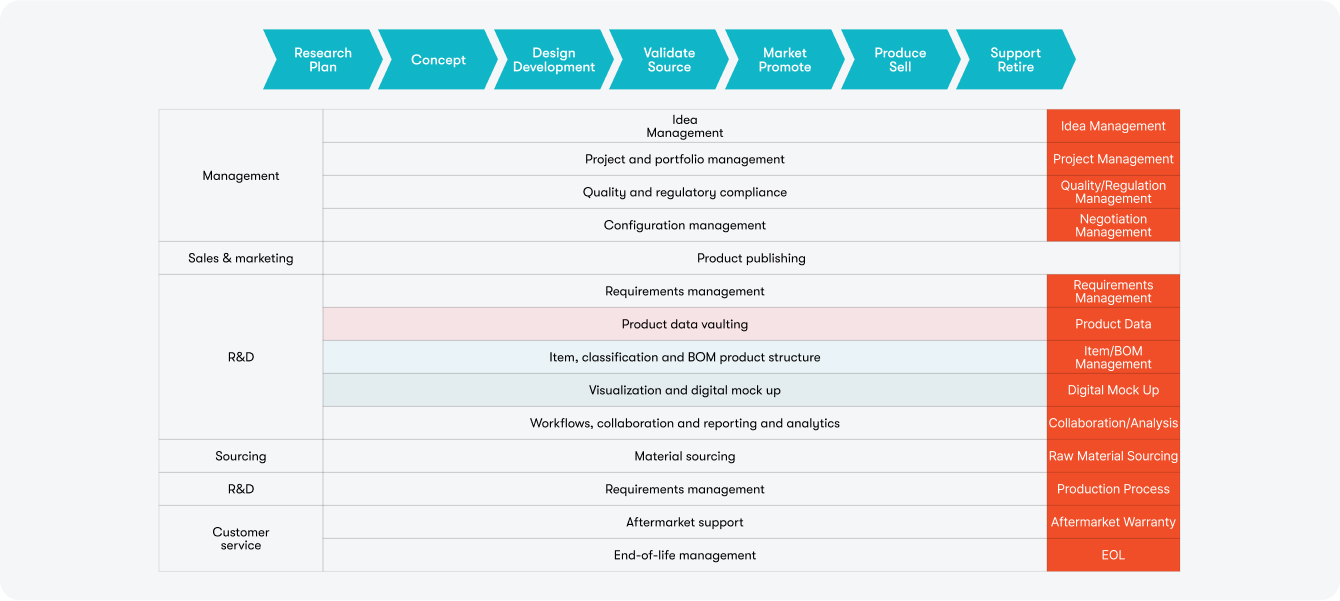

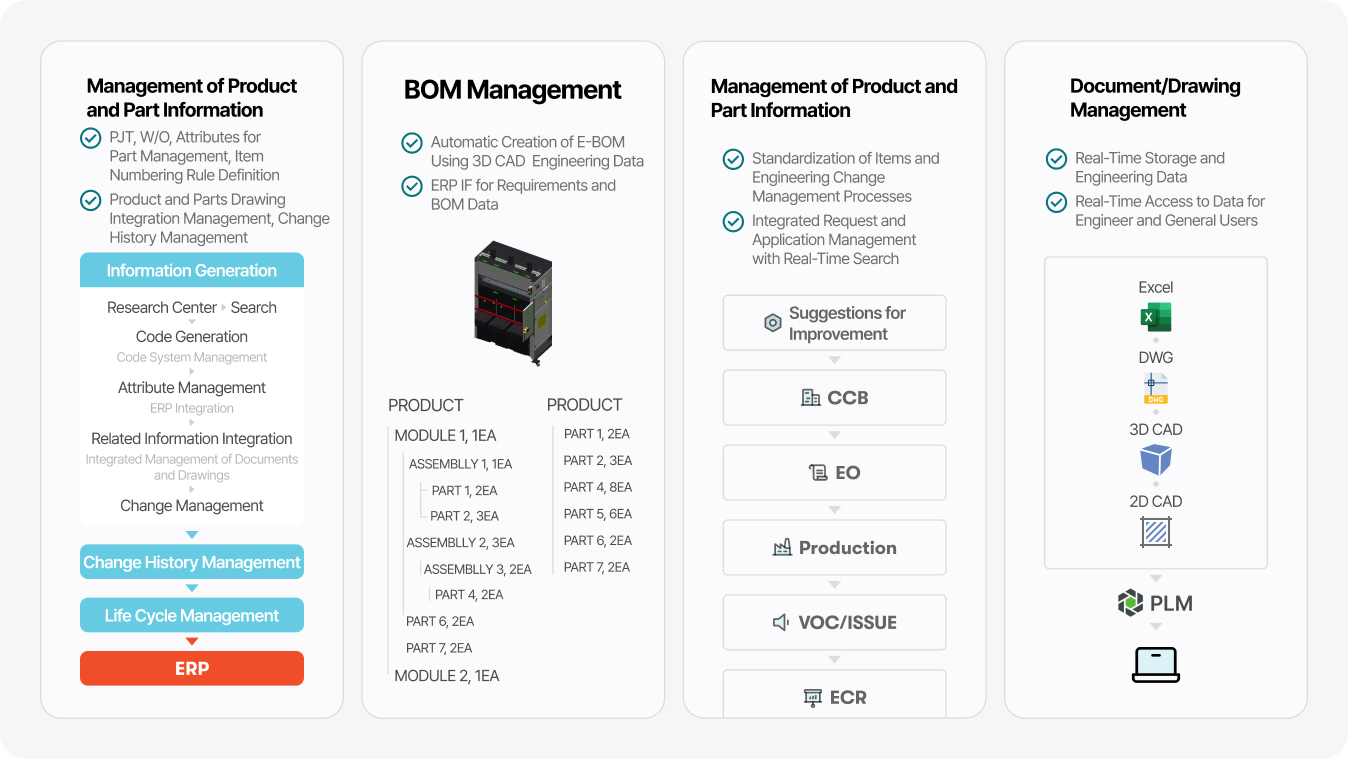

The TEPS-PLM (Product Lifecycle Management) solution, built on UDS’s proprietary Total Enterprise Process Solution,

enables end-to-end data management from design to production, leveraging PTC’s Windchill PLM system.

PLM is a solution that supports the generation and sharing of information across the entire process,

from product design and production to use and disposal. Project management and product value management are optimized

based on the solution, enabling efficient process operation.

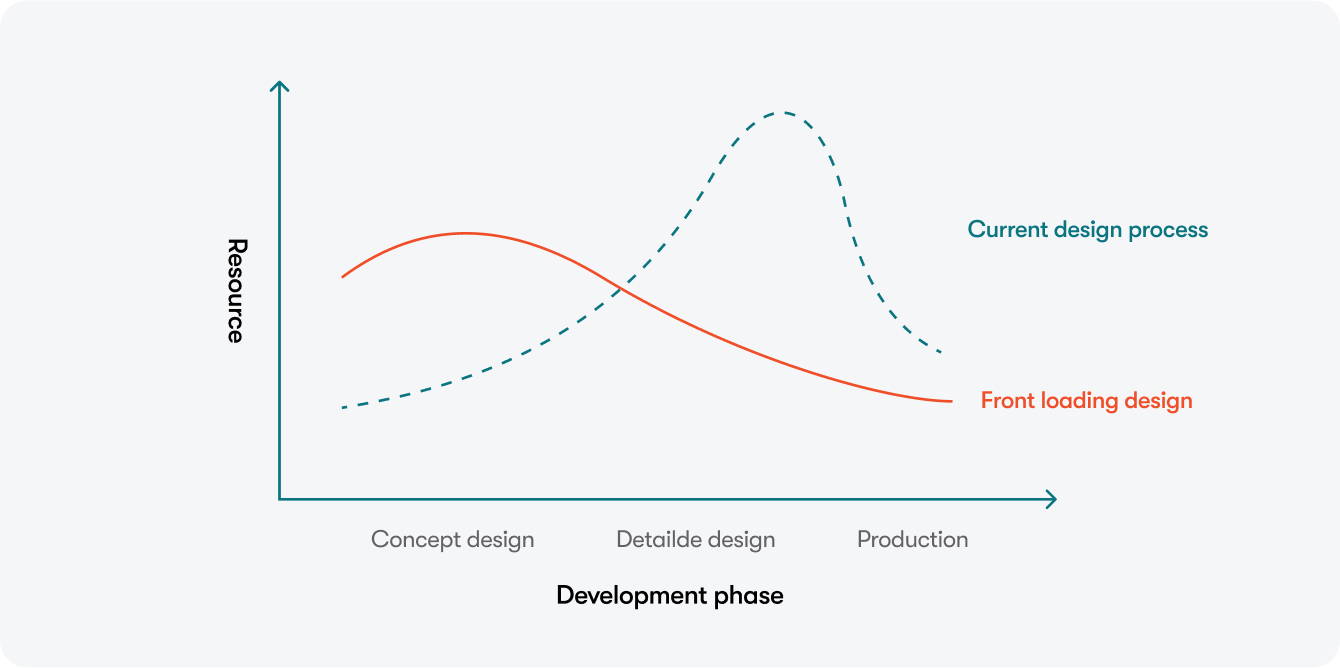

With TEPS-PLM, potential issues that may arise in the later stages of the business process are proactively resolved,

enabling 'Front Loading' to reduce unnecessary time and costs while strengthening the company’s competitiveness.

Design data-based information — including product and part data management, BOM management, change management,

and document/drawing management — is managed in real time. The E-BOM and drawing information

in TEPS-PLM enables work to proceed using identical data across the company with IF to TEPS-SBMS and ERP.

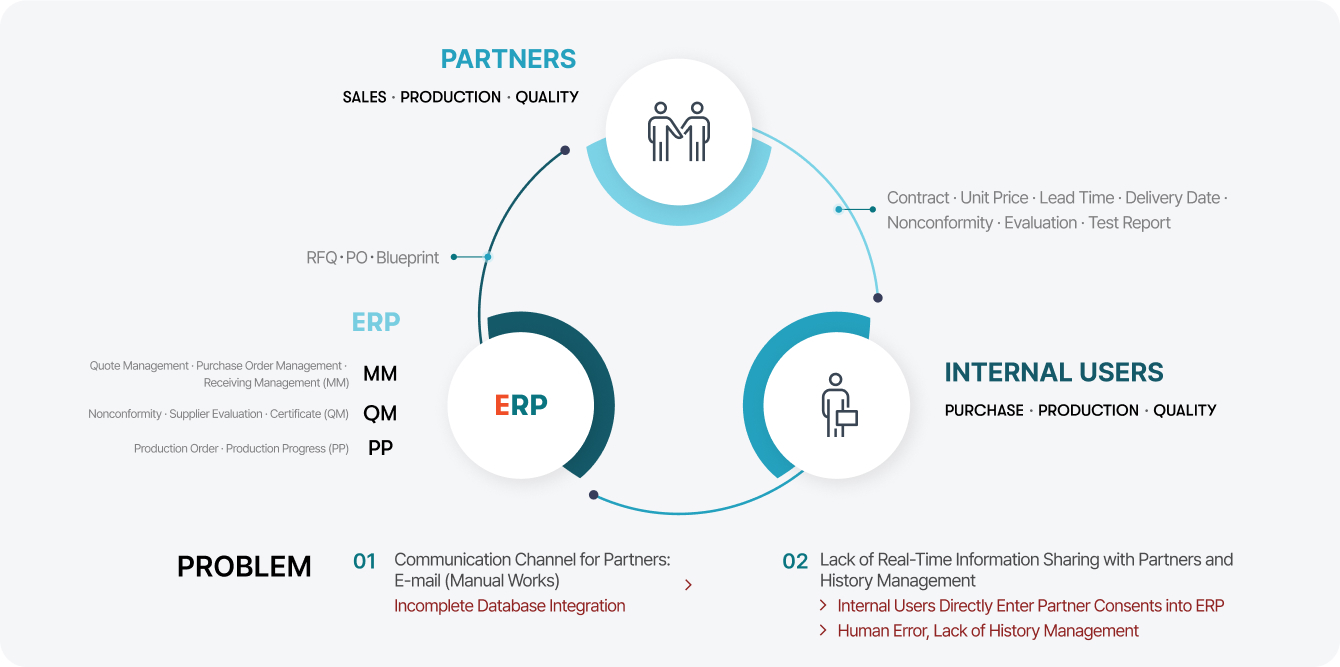

The TEPS-SCM solution efficiently supports subcontractor management through purchase management, quality management,

and change management. Previously unsystemized work processes could cause business disruptions and data loss

due to difficulties in real-time data sharing and history management, resulting in increased working hours.

TEPS-SCM greatly improves work efficiency through real-time data sharing with partners

and work progress history management.

It provides part-specific quotation management, order management, and delivery management functions.

It has a system for storing and retrieving the complete history, including CoAs, Incoming Inspection,

and nonconforming work management. With this, systematic product quality management is achieved,

maximizing the company's margin. In addition, work progress by stage and by authority is managed

through separate portal configurations for orderers and partners.

Data in TEPS-SCM is linked with ERP (MES) to avoid duplication of effort and maintain data coherency.

PART and BOM data, generated in TEPS-PLM, is linked to TEPS-SCM and are utilized as the primary data

for quoting and ordering. The quotation and ordering data generated in TEPS-SCM is linked with ERP (MES)

to serve as core data for production and shipment processes.